The Engineering Behind the Rotational Moulding Process

Rotational moulding is an industrial process used to transform thermoplastic materials into a wide variety of parts. It involves placing a mould shaped like the desired component inside a preheated machine.

The process develops in five stages. The first is loading, which consists of placing the raw material inside the mould. Next comes the transformation stage, during which the mould rotates inside the oven on two axes — vertical and horizontal — allowing the melted material to adhere uniformly to the inner surface. Then follows the cooling phase, with continued rotation until completion, ensuring a homogeneous wall thickness.

During the demoulding stage, the part is removed from the mould. Finally, the finishing phase eliminates any excess material, particularly around the mould joints.

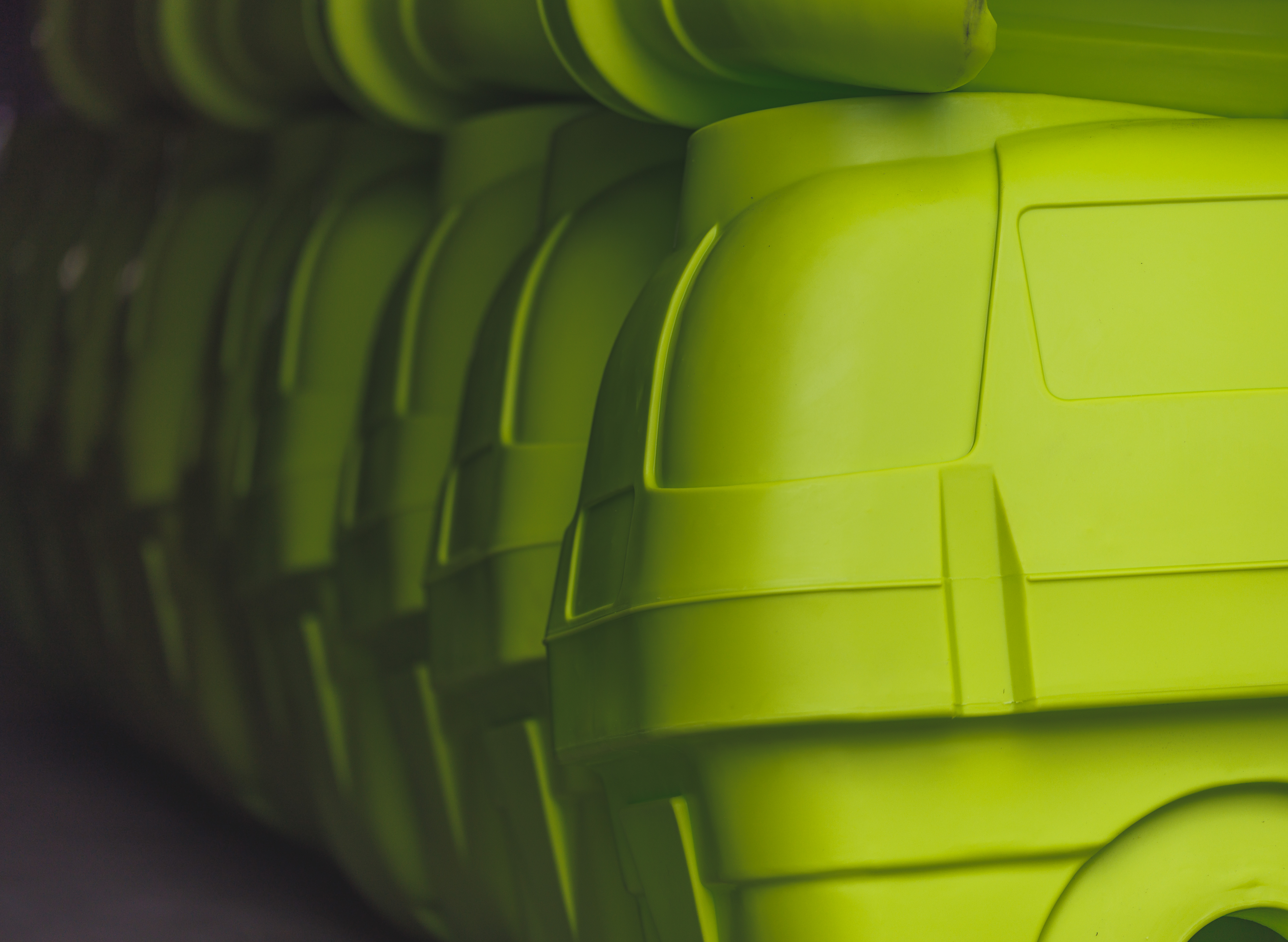

The moulds, made of cast aluminium or sheet metal, are essential elements in the process. The quality of the finished parts largely depends on the precision of their design.

Efficiency, durability and precision

Rotational moulding offers economic advantages over other processes such as injection moulding, blow moulding or vacuum forming, allowing lower mold production costs — especially for medium or small series.

In addition, it enables the creation of large-scale parts with more sophisticated designs.

With a well-planned project, multiple parts can be combined into a single piece, reducing costs and increasing the strength of the final product.

This technique has been gaining more relevance due to its versatility. It is used in diverse sectors such as decoration, toys, technical parts, and also in the production of tanks, reservoirs, and containers.

The growing demand for more eco-friendly solutions, innovative design, and greater adaptability has been a key factor in the expanding use of rotomoulding.